Just in time for the Holidays, we've come across two unique lines of paper ideal for the project your boss hasn't told you about. By that I mean the company Christmas card. The one that needs to be mailed the first week of December. Which is sooner than you think.

CTI Paper USA provides the following prose to describe their ASPIRE Petallics line, and I will quote verbatim being somewhat adjective-challenged on my own:

Capture the essence of life’s finer things with ASPIRE Petallics. A distinctly elegant canvas for your most discerning creative, ASPIRE Petallics sets the standard for sophistication.

The most impressive part of this flowery statement is that it's true. The distributors stocking information for this paper describes it as having a "Mica Finish", and if I had the shorten the description to two words those would do it. This stock comes in a white digital-compatible color which they (inexplicably) call "Beargrass", as well as several others certified for offset printing. Matching envelopes are available in three "A" sizes.

So far we have run business cards and a dinner program on this paper at our shop and the customers loved the results. (I've also seen some Holiday cards run commercially that were also impressive.) Please contact me directly to see some samples.

ReichPaper has similar superlative language to offer regarding their SHINE line of papers, and, again, I'm forced to admit they can be forgiven their enthusiasm:

SHINE brings a subtle shimmer to every design, combining natural minerals with organic pigments, for a rich, luminous effect.

Both of these stocks feature a bright, shimmery finish capable of adding a three dimensional feel to even a very plain vanilla design. Because they behave like a coated stock the printing colors, offset or digital, remain bright. The only drawback is fairly high cost, but these runs tend to be short, and therefore not much paper has to be bought. I think people are getting a lot of visual bang for the buck.

Please let me know if you would like to see samples of these papers...the personality of each finish is just not possible to convey online. We think there's going to be a lot of people wanting to try them out!

I've been looking at printing paper for almost thirty years and have never seen such a scarcity of interesting brands. Consolidation and belt tightening in the paper business are absolutely ruining the selection, and that is a major reason why these two lines are so exciting! This can give you an ace in the hole when the design request shows up at the eleventh hour!

Thanks!

Hugh Butler

Your friend in the printing business

Aspire Petallics and SHINE are registered trademarks of their respective manufacturers

Wednesday, November 17, 2010

Wednesday, November 3, 2010

Here is a Hymn to the 188C and the 4525C

If you're a friend of Florida State University you'll recognize the following verse, and a smile, or even a tear, may appear as you read:

Here is a hymn to the Garnet and Gold, ringing to the sky.

Here is a song for the men and women bold. Sing with heads held high.

Striving ere to seek to know, Fight for victory.

Alma Mater, this our song to you. Echoes, F.S.U.

The University Communications Office cares deeply about Garnet and Gold, particularly after having invested considerable effort in a 2009 update of FSU's visual identity. This update brought a contemporary and consistent look to all visual elements of FSU. The picture below shows about ten years and three iterations of design evolution between the old seal on the left, (ca. 1990), and one of the many new versions available today. See this link for a comprehensive guide to usage and different formats available.

(Click on image to see full size.)

Designers, printers, web developers, and anyone else involved with FSU identity can find all the guidance they need at FSU Voice and Visual Systems. This landing page, and then its link to the main Voice and Visual System Document (upper left corner) contain exhaustive graphics standards for everything from letterhead to vehicles to architecture and signage. Downloadable artwork is also available from the main page for anyone with an FSU Login and Password.

The section within the Voice and Visual System Document I want to highlight is the one devoted to color as many print jobs show up at our shop with incorrect colors specified within the file.

(Click on image to view full size.)

Note in the graphic above that FSU has taken great care to specify spot color Pantone numbers as well as their CMYK, RGB and Hex equivalents. To further refine the standards, distinct Pantone numbers for coated and uncoated paper are provided for the Garnet, and a Pantone Metallic number for the Gold if it will utilize metallic ink. (On succeeding pages of the Color Guide section specifications are provided for building color gradients of each.) All of this represents a tremendous amount of work on the part of FSU, and a unique opportunity to get your project off on the right foot.

If you don't know which color model your actual printing will use, it's important to find out before proceeding to first base with the file.

Beyond the general note that the University Communications Office cares deeply about these standards two things are important to understand; one is that FSU will help in any way they can to make this information accessible and understandable, and the other is that compliance is not optional. Like any major entity, FSU has a huge stake in projecting and protecting a unified brand.

On the latter point, compliance, you must become familiar not only with the guidelines, but also trademark and licensing issues. The last thing you want to happen is have your product look like a mismatch or, even worse, to get in serious trouble by misuse of copyrighted or trademarked material.

To end on a positive note, I've always found Frances Conaway (fconaway@fsu.edu or 644-2913) at University Communications to be an extremely helpful person for information beyond what's on the web page. She is one of many people who care deeply about FSU, and was kind enough to preview and help me with this post.

With best wishes to all friends of the printing business, both on and off campus,

Hugh Butler

Your friend in the printing business

Here is a hymn to the Garnet and Gold, ringing to the sky.

Here is a song for the men and women bold. Sing with heads held high.

Striving ere to seek to know, Fight for victory.

Alma Mater, this our song to you. Echoes, F.S.U.

The University Communications Office cares deeply about Garnet and Gold, particularly after having invested considerable effort in a 2009 update of FSU's visual identity. This update brought a contemporary and consistent look to all visual elements of FSU. The picture below shows about ten years and three iterations of design evolution between the old seal on the left, (ca. 1990), and one of the many new versions available today. See this link for a comprehensive guide to usage and different formats available.

(Click on image to see full size.)

Designers, printers, web developers, and anyone else involved with FSU identity can find all the guidance they need at FSU Voice and Visual Systems. This landing page, and then its link to the main Voice and Visual System Document (upper left corner) contain exhaustive graphics standards for everything from letterhead to vehicles to architecture and signage. Downloadable artwork is also available from the main page for anyone with an FSU Login and Password.

The section within the Voice and Visual System Document I want to highlight is the one devoted to color as many print jobs show up at our shop with incorrect colors specified within the file.

(Click on image to view full size.)

Note in the graphic above that FSU has taken great care to specify spot color Pantone numbers as well as their CMYK, RGB and Hex equivalents. To further refine the standards, distinct Pantone numbers for coated and uncoated paper are provided for the Garnet, and a Pantone Metallic number for the Gold if it will utilize metallic ink. (On succeeding pages of the Color Guide section specifications are provided for building color gradients of each.) All of this represents a tremendous amount of work on the part of FSU, and a unique opportunity to get your project off on the right foot.

If you don't know which color model your actual printing will use, it's important to find out before proceeding to first base with the file.

Beyond the general note that the University Communications Office cares deeply about these standards two things are important to understand; one is that FSU will help in any way they can to make this information accessible and understandable, and the other is that compliance is not optional. Like any major entity, FSU has a huge stake in projecting and protecting a unified brand.

On the latter point, compliance, you must become familiar not only with the guidelines, but also trademark and licensing issues. The last thing you want to happen is have your product look like a mismatch or, even worse, to get in serious trouble by misuse of copyrighted or trademarked material.

To end on a positive note, I've always found Frances Conaway (fconaway@fsu.edu or 644-2913) at University Communications to be an extremely helpful person for information beyond what's on the web page. She is one of many people who care deeply about FSU, and was kind enough to preview and help me with this post.

With best wishes to all friends of the printing business, both on and off campus,

Hugh Butler

Your friend in the printing business

Friday, April 23, 2010

Tradecraft

A few Fridays ago Terry Herbst, longtime press operator at our shop, retired after twenty years with the company. To give you an idea of his tenure let's note he printed one of our client's newsletters one hundred and sixty five times, and did so without any memorable problems. (Years prior to his stay here, Terry's Army unit in Vietnam also read newsletters that he printed.) Reflecting on Terry's career got me thinking about the things that have changed in our business, and, more importantly, the things that have not.

It's tempting to lump press operators into the larger category of skilled trades such as fabricating or construction. All trades involve the application of basic methods to accomplish the task at hand, but the skills required to run a printing press go further. This is true because of the intangible and fluid nature of the process, and the leap of faith required every time a press operator cranks up on a production run.

The leap of faith is necessary because, at the top of a run, press operators know that they only have limited control over what is going to happen next. Also, that no matter how it goes, they will be held responsible. Those factors that are not under their control include: the quality and personality of the paper; the atmospheric conditions in the shop such as temperature and humidity; the skills of the personnel upstream in the production process; and the fact that wet ink looks different than it will twelve hours later when dry. If you are about to commit $3,000 of the company's paper to a job it takes a lot of guts to push that "RUN" button.

So, what's changed? What makes the life of a press operator different than ten years ago?

The easy answer is digital pre-press and the high quality plates it produces. The elimination of hand assembled film in the platemaking process, and its replacement by laser platesetters, allows for a highly precise process. The plates delivered to the press are cleaner, line up faster, and require less tinkering. All of this gets you to the top of the run quickly; with less frustration and fewer false starts. No operator I know would willingly switch back to the "good old days".

The more complicated trend is the move to all-digital printing, (currently for shorter runs), with no plates at all. These machines are fundamentally different than conventional offset presses.

This leads to a conundrum in the operator's life, because it upsets the balance between art and science. (By art I refer to skill based on intuition.) There is much less interaction between the machine and the operator, and finely tuned adjustments cannot be made during the run. This could relegate the operator to the role of "mouse jockey", but fear not; here comes the basic fact which will never change.

Customers care deeply about the quality of work they receive. (I learned this firsthand at a print shop where I made all my own customer deliveries.) In order for the high-fives and victory lap to commence a lot of people have to do a lot of things right...and key to that success are the tradespeople who put the image down on the sheet. Any tradesperson "worth his salt" knows that the customer will scrutinize the work, and takes the steps necessary to be proud of what goes out the door.

This pride has always been the source of good tradecraft. Regardless of the level of technology, high quality work comes from equipment that is well cared for, run by people who give a damn about what they're doing. The knowledge that their extra effort make a difference, and that the customer deserves it, is what distinguishes a tradesperson from someone just punching the clock.

With sincere thanks to Terry for his millions of good impressions, and best wishes to him and Linda in the years ahead,

Hugh Butler

Your friend in the printing business

It's tempting to lump press operators into the larger category of skilled trades such as fabricating or construction. All trades involve the application of basic methods to accomplish the task at hand, but the skills required to run a printing press go further. This is true because of the intangible and fluid nature of the process, and the leap of faith required every time a press operator cranks up on a production run.

The leap of faith is necessary because, at the top of a run, press operators know that they only have limited control over what is going to happen next. Also, that no matter how it goes, they will be held responsible. Those factors that are not under their control include: the quality and personality of the paper; the atmospheric conditions in the shop such as temperature and humidity; the skills of the personnel upstream in the production process; and the fact that wet ink looks different than it will twelve hours later when dry. If you are about to commit $3,000 of the company's paper to a job it takes a lot of guts to push that "RUN" button.

So, what's changed? What makes the life of a press operator different than ten years ago?

The easy answer is digital pre-press and the high quality plates it produces. The elimination of hand assembled film in the platemaking process, and its replacement by laser platesetters, allows for a highly precise process. The plates delivered to the press are cleaner, line up faster, and require less tinkering. All of this gets you to the top of the run quickly; with less frustration and fewer false starts. No operator I know would willingly switch back to the "good old days".

The more complicated trend is the move to all-digital printing, (currently for shorter runs), with no plates at all. These machines are fundamentally different than conventional offset presses.

This leads to a conundrum in the operator's life, because it upsets the balance between art and science. (By art I refer to skill based on intuition.) There is much less interaction between the machine and the operator, and finely tuned adjustments cannot be made during the run. This could relegate the operator to the role of "mouse jockey", but fear not; here comes the basic fact which will never change.

Customers care deeply about the quality of work they receive. (I learned this firsthand at a print shop where I made all my own customer deliveries.) In order for the high-fives and victory lap to commence a lot of people have to do a lot of things right...and key to that success are the tradespeople who put the image down on the sheet. Any tradesperson "worth his salt" knows that the customer will scrutinize the work, and takes the steps necessary to be proud of what goes out the door.

This pride has always been the source of good tradecraft. Regardless of the level of technology, high quality work comes from equipment that is well cared for, run by people who give a damn about what they're doing. The knowledge that their extra effort make a difference, and that the customer deserves it, is what distinguishes a tradesperson from someone just punching the clock.

With sincere thanks to Terry for his millions of good impressions, and best wishes to him and Linda in the years ahead,

Hugh Butler

Your friend in the printing business

Monday, April 5, 2010

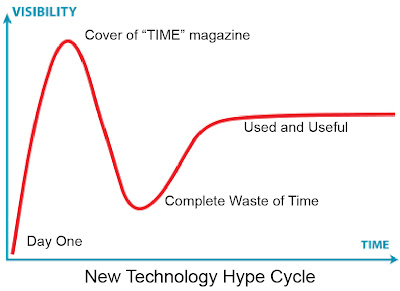

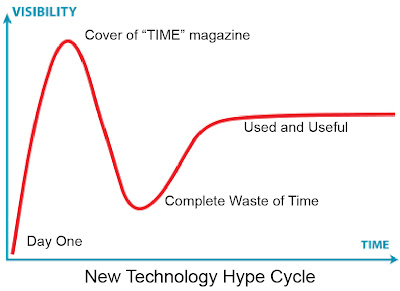

New Technologies and the Hype Cycle

The commentary cloud surrounding social media has made much of the "Hype Cycle" of new technology. I thought it would be helpful to place some printing technologies along this curve. Because this blog strives for original content, certain liberties have been taken with the following graphic explanation:

Our business has brought several new technologies into the mainstream with significant benefit to our customers. They're evaluated here in no particular order:

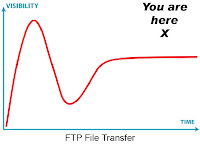

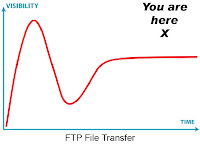

FTP File Transfer: File Transfer Protocol, or FTP, is a fully mature method of communicating production files to a print shop. Depending on their client profile printers use a dedicated FTP server, providing secure access to a client area, or a browser based system. Either way, files too large to email efficiently can be sent to or from the shop. For people like me, who used to have to drive everywhere to pick up disks, this technology is invaluable, and customers benefit from the ability to get their job inside the shop in minutes. If your printer doesn't offer FTP, clients can do it themselves by using services such as box.net or yousendit. My yousendit dropbox, for example, is here and requires no special software, login, or password.

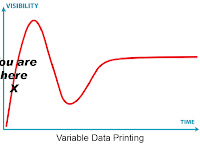

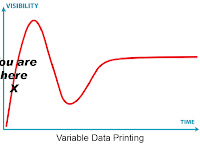

Variable Data: "Mail Merge" on steroids, this technology has run out in front of user demand, and is often present in a local printing market just waiting for people to catch on. Digital printing technology makes the inclusion of customized data in a printed piece relatively easy, and usually ties that component into a larger campaign. Offer numbers, customer numbers, product keys, customer names, postal addressing, and various security features are all capable of being incorporated; all that is required is imaginative thinking and collaboration with your provider.

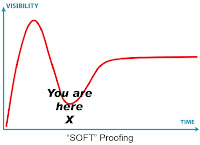

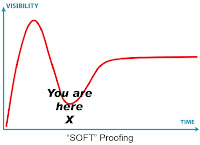

Soft Proofing: a/k/a onscreen proofing is a great way speed up and economize the approval process assuming the following: 1) You are a fastidious proofreader before submitting your file to the printer and 2)have trained everyone in your office to be the same. 3) You are a technical super-pro with a longstanding track record, and 4) a compulsive gambler. All the rest of us mortals should stick to hardcopy proofing. I personally do not know anyone who can proofread onscreen to a level which can guarantee a project will be error free. I know this to be true because I see our customers spend thousands of dollars correcting simple editing errors which are only caught in hardcopy form at our proof stage.

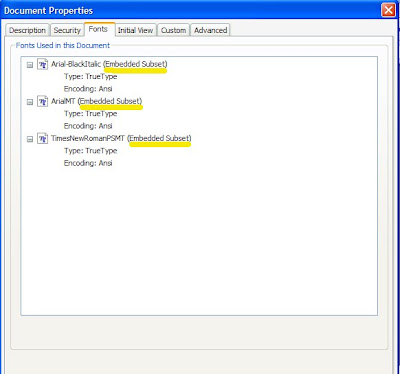

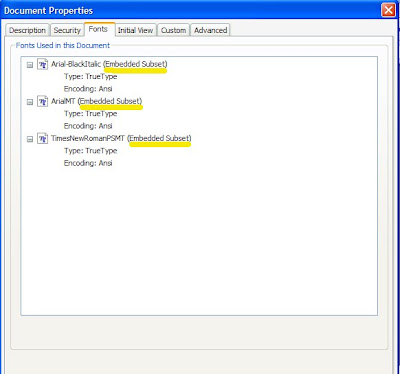

PDF submission: Most commercial shops use PDF based workflow systems because of their compact and reliable nature. Since the individual pages which make up your layout are going to be converted to PDF anyway customers can (and sometimes must) perform that step themselves and simplify file submission. There are a few common problems, however, which will fill you with a sense of rejection; most important, the file must be created with all fonts embedded.

The defining feature of a PDF file is its ability to render properly no mater which computer it’s on. Key to this ability is the file’s willingness to carry within itself a copy of all the fonts which were used by the original program (Word, InDesign, etc). Unfortunately, this feature can be defeated by the home computers desire to keep the file size small, and thus omit the internal font copies. It is imperative that the settings used to create the PDF instruct that the fonts be “embedded” or else the file will, without warning, substitute whatever fonts may be available in its new neighborhood. This can cause problems ranging in size from troubling to disastrous.

The solution is simple and easy to check. First, use the “Press Quality” settings from the menu at the PDF creation step. (For Microsoft products also be sure the “never embed” window is empty.) Second, after the file is created, go to File>Properties>Fonts to be sure ALL fonts listed are followed by the term “embedded subset” as in the following picture.

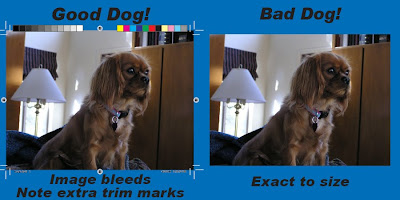

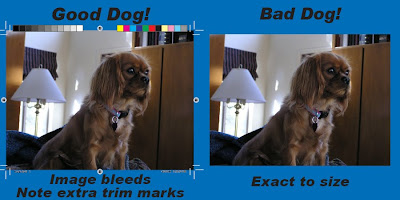

Second most important, the file must allow for extra image outside the trim size of the file if the printed image “bleeds” off the edge. My dog, Lassie, will now demonstrate, although you should click on the picture to see it full size:

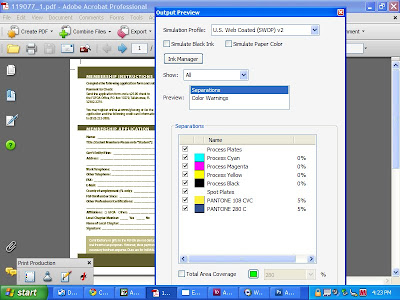

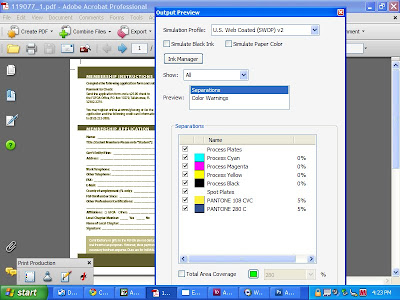

Third most important, check to see that you ended up with the colors you intended for printing. The step in Acrobat is Advanced>Print Production>Output Preview and you'll see something like the following, and there is NO END of interesting details you can learn about your file:

I'm happy to return to this page after a two month hiatus during which the actual printing business was quite hectic. Many wishes came true at our shop, with the result being my neglect of you loyal readers. I hope the first quarter of 2010 was encouraging for you as well, and look forward to your feedback online.

Sincerely,

Hugh Butler

Your Friend in the Printing Business

Our business has brought several new technologies into the mainstream with significant benefit to our customers. They're evaluated here in no particular order:

FTP File Transfer: File Transfer Protocol, or FTP, is a fully mature method of communicating production files to a print shop. Depending on their client profile printers use a dedicated FTP server, providing secure access to a client area, or a browser based system. Either way, files too large to email efficiently can be sent to or from the shop. For people like me, who used to have to drive everywhere to pick up disks, this technology is invaluable, and customers benefit from the ability to get their job inside the shop in minutes. If your printer doesn't offer FTP, clients can do it themselves by using services such as box.net or yousendit. My yousendit dropbox, for example, is here and requires no special software, login, or password.

Variable Data: "Mail Merge" on steroids, this technology has run out in front of user demand, and is often present in a local printing market just waiting for people to catch on. Digital printing technology makes the inclusion of customized data in a printed piece relatively easy, and usually ties that component into a larger campaign. Offer numbers, customer numbers, product keys, customer names, postal addressing, and various security features are all capable of being incorporated; all that is required is imaginative thinking and collaboration with your provider.

Soft Proofing: a/k/a onscreen proofing is a great way speed up and economize the approval process assuming the following: 1) You are a fastidious proofreader before submitting your file to the printer and 2)have trained everyone in your office to be the same. 3) You are a technical super-pro with a longstanding track record, and 4) a compulsive gambler. All the rest of us mortals should stick to hardcopy proofing. I personally do not know anyone who can proofread onscreen to a level which can guarantee a project will be error free. I know this to be true because I see our customers spend thousands of dollars correcting simple editing errors which are only caught in hardcopy form at our proof stage.

PDF submission: Most commercial shops use PDF based workflow systems because of their compact and reliable nature. Since the individual pages which make up your layout are going to be converted to PDF anyway customers can (and sometimes must) perform that step themselves and simplify file submission. There are a few common problems, however, which will fill you with a sense of rejection; most important, the file must be created with all fonts embedded.

The defining feature of a PDF file is its ability to render properly no mater which computer it’s on. Key to this ability is the file’s willingness to carry within itself a copy of all the fonts which were used by the original program (Word, InDesign, etc). Unfortunately, this feature can be defeated by the home computers desire to keep the file size small, and thus omit the internal font copies. It is imperative that the settings used to create the PDF instruct that the fonts be “embedded” or else the file will, without warning, substitute whatever fonts may be available in its new neighborhood. This can cause problems ranging in size from troubling to disastrous.

The solution is simple and easy to check. First, use the “Press Quality” settings from the menu at the PDF creation step. (For Microsoft products also be sure the “never embed” window is empty.) Second, after the file is created, go to File>Properties>Fonts to be sure ALL fonts listed are followed by the term “embedded subset” as in the following picture.

Second most important, the file must allow for extra image outside the trim size of the file if the printed image “bleeds” off the edge. My dog, Lassie, will now demonstrate, although you should click on the picture to see it full size:

Third most important, check to see that you ended up with the colors you intended for printing. The step in Acrobat is Advanced>Print Production>Output Preview and you'll see something like the following, and there is NO END of interesting details you can learn about your file:

I'm happy to return to this page after a two month hiatus during which the actual printing business was quite hectic. Many wishes came true at our shop, with the result being my neglect of you loyal readers. I hope the first quarter of 2010 was encouraging for you as well, and look forward to your feedback online.

Sincerely,

Hugh Butler

Your Friend in the Printing Business

Thursday, January 7, 2010

Don't Tax Me, bro'....BZZT!

As someone who spent the formative part of his career in New Hampshire, a fairly Libertarian state, I devoted a lot of trial and error to my business dealings with sales tax after moving to Florida. The Granite State has no such tax, or income tax for that matter, so I guess I considered the whole thing kind of silly. Our highly skilled and efficient bookkeeper, Jennifer Walker, who has survived a full fledged sales tax audit, thinks otherwise and I have learned to defer to her wisdom.

Herewith is my best effort at saving you from the trouble I caused myself (and Jennifer). It is not to be considered professional advice, but a laypersons discussion of issues we run into here at the print shop. Before taking any action be sure to consult an actual tax professional.

Florida sales tax (plus local county kicker) must be collected on the sale of any printing project unless the buyer has furnished, in advance of the sale, one of two Florida Department of Revenue certificates. (This assumes the job is produced by a Florida company for delivery within the state...if the entirety of the product ships outside the state no tax is due.)

DR-14 Consumer's Certificate of Exemption is the proof that must be furnished by an entity who does not have to pay Florida sales tax by virtue of their non-profit or governmental status. This group would include schools, churches, government offices, and most charities. The DR-14 should not be confused with the Federal IRS form which defines their status as "non-profit" and exempt from Federal income tax...that is a separate issue entirely and will not suffice for FL DOR purposes.

The most common pitfalls regarding this exemption are 1) that the certificate has not been applied for and granted, or 2) the tax exempt entity is the end user, but not the payer of the printer's invoice. The latter situation arises when the job is ordered and paid for by a third party, such as an ad agency, who may not utilize the tax exempt status of the end user in their intermediate transaction with the printer. We worked on a job recently where the agency pre-billed a non-profit for printing without including sales tax, but was then liable for it in their transaction with the shop. The 7.5% tax ate up half their mark-up. The solution to this problem moves us to the next form.

DR-13 Florida Annual Resale Certificate for Sales Tax is proof of a buyer's eligibility to make purchases exempt from Florida sales tax when the goods will be re-sold to a subsequent end user, with appropriate tax to be paid on that final transaction. In this scenario the buyer becomes a seller and is then responsible for determination of the end-user's tax status and collecting any tax due for submission to the state. The resale certificate requires a fair amount of record keeping and reporting, but is the most legitimate way of doing business if you routinely act as a printing "broker".

The most common pitfalls with resale are 1) the certificate must be presented to the vendor prior to the first transaction and then resubmitted each year they continue to do business, 2) the "Presented To" and "Presented By" section at the bottom must be filled out, and 3) the goods must actually be for resale...you can't buy your own business cards this way. It's important to communicate to the print shop whether the job is for resale or not.

To sum up: Be prepared to pay sales tax on any purchase of printing produced and delivered within Florida unless one of the two certificates has been presented, and further that the entity named on the check or credit card tendered for payment MUST match both the name on the invoice and the name on the certificate of exemption. If all three don't match the exemption can't be honored because of the potential for fraud.

It's the customer's responsibility determine the tax status of the job, and to communicate with the shop if an exemption is appropriate so the transaction can be processed appropriately. Failure to do so leads to unnecessary paperwork and a "retrospective" approach which may viewed in a dim light by the Florida DOR in the event of an audit. This is no joke...just ask Jennifer, who spent several days with DOR auditors some years ago and learned many lessons as a result.

On a final note, before you consider moving there to escape sales and income taxes, remember this; when you open your New Hampshire property tax bill, or register a car up there, it's best to be seated. The money has to come from somewhere.

It's also a little snowy just now...

Hoping 2010 is off to a good start,

Hugh Butler

Your friend in the printing business

Herewith is my best effort at saving you from the trouble I caused myself (and Jennifer). It is not to be considered professional advice, but a laypersons discussion of issues we run into here at the print shop. Before taking any action be sure to consult an actual tax professional.

Florida sales tax (plus local county kicker) must be collected on the sale of any printing project unless the buyer has furnished, in advance of the sale, one of two Florida Department of Revenue certificates. (This assumes the job is produced by a Florida company for delivery within the state...if the entirety of the product ships outside the state no tax is due.)

DR-14 Consumer's Certificate of Exemption is the proof that must be furnished by an entity who does not have to pay Florida sales tax by virtue of their non-profit or governmental status. This group would include schools, churches, government offices, and most charities. The DR-14 should not be confused with the Federal IRS form which defines their status as "non-profit" and exempt from Federal income tax...that is a separate issue entirely and will not suffice for FL DOR purposes.

The most common pitfalls regarding this exemption are 1) that the certificate has not been applied for and granted, or 2) the tax exempt entity is the end user, but not the payer of the printer's invoice. The latter situation arises when the job is ordered and paid for by a third party, such as an ad agency, who may not utilize the tax exempt status of the end user in their intermediate transaction with the printer. We worked on a job recently where the agency pre-billed a non-profit for printing without including sales tax, but was then liable for it in their transaction with the shop. The 7.5% tax ate up half their mark-up. The solution to this problem moves us to the next form.

DR-13 Florida Annual Resale Certificate for Sales Tax is proof of a buyer's eligibility to make purchases exempt from Florida sales tax when the goods will be re-sold to a subsequent end user, with appropriate tax to be paid on that final transaction. In this scenario the buyer becomes a seller and is then responsible for determination of the end-user's tax status and collecting any tax due for submission to the state. The resale certificate requires a fair amount of record keeping and reporting, but is the most legitimate way of doing business if you routinely act as a printing "broker".

The most common pitfalls with resale are 1) the certificate must be presented to the vendor prior to the first transaction and then resubmitted each year they continue to do business, 2) the "Presented To" and "Presented By" section at the bottom must be filled out, and 3) the goods must actually be for resale...you can't buy your own business cards this way. It's important to communicate to the print shop whether the job is for resale or not.

To sum up: Be prepared to pay sales tax on any purchase of printing produced and delivered within Florida unless one of the two certificates has been presented, and further that the entity named on the check or credit card tendered for payment MUST match both the name on the invoice and the name on the certificate of exemption. If all three don't match the exemption can't be honored because of the potential for fraud.

It's the customer's responsibility determine the tax status of the job, and to communicate with the shop if an exemption is appropriate so the transaction can be processed appropriately. Failure to do so leads to unnecessary paperwork and a "retrospective" approach which may viewed in a dim light by the Florida DOR in the event of an audit. This is no joke...just ask Jennifer, who spent several days with DOR auditors some years ago and learned many lessons as a result.

On a final note, before you consider moving there to escape sales and income taxes, remember this; when you open your New Hampshire property tax bill, or register a car up there, it's best to be seated. The money has to come from somewhere.

It's also a little snowy just now...

Hoping 2010 is off to a good start,

Hugh Butler

Your friend in the printing business

Subscribe to:

Posts (Atom)