Friday, December 19, 2008

Three secrets NOT to keep

Apparently, there are three things print buyers are ashamed to share, and they are as follows: How many are needed? What needs to happen for proof approval? Where do they go when the job is finished? These questions have been touched on in previous posts, but their recurring omission indicates they deserve special attention.

"I need to get started right away, I'll tell you the quantity later" is self-contradictory. If you REALLY need to get started right away, include the quantity when the order is placed. It allows paper to be purchased, has an impact on how the job will be run, and, most importantly, precludes the chance for an error to be made if the quantity is plugged in later. Please note that the quantity is the grand total of your mailing list plus extras for the mail processor, plus however many you want leftover.

"If you can get us the proof in the morning, the committee will look at it immediately" is also bad tidings. The more people who need to approve the printers proof the greater the chance that it will not survive intact. This is fine if you're not on deadline and don't care about the cost of changes. (If you meet someone like that send them my way, because, as of yet, we are unacquainted.) In order to schedule a job accurately it's important to be honest about what needs to happen for approval so that time can be blocked out for careful review. If you don't at least have a discussion with the print vendor, that's not possible.

"I'm not sure where they go, can we decide that later"? The answer, of course, is yes...but that doesn't make it OK. First, the nature of the destination may have a bearing on packaging and delivery details such as; in boxes or on pallets, loading dock or inside delivery, etc. Second, if the destination is out of town the delivery date may need to be a day (or three) earlier to allow for travel. Last, someone like me doesn't need an extra opportunity for screw-ups with information is coming in as the job is trying to go out.

Sometimes, like a marquee quarterback, the printing team needs to assess the situation and "call an audible" as the job is in progress. It's actually exciting, and when a plan flows, and adjustments are made, and the project succeeds it's a great feeling. I'm not kidding...it's exhilarating! Any good vendor should be able to stick with you through this kind of situation, but just because you CAN doesn't mean you SHOULD.

More often than not "Boring is best". Place the order with complete information, narrow your approval group to the minimum number possible, and think through in advance where all this stuff (which may be several hundred pounds) needs to go. That way you can depend on other facets of your life for the adrenaline rush...like bungee jumping...or parenthood.

With best wishes for the Holiday Season,

Hugh Butler

Your friend in the printing business

Friday, December 5, 2008

"It's my budget, Doc"...Letters collide with numbers

Wednesday, November 26, 2008

Happy Thanksgiving

Friday, November 21, 2008

Lost in translation

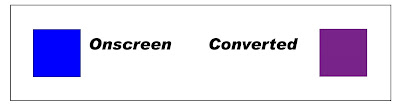

This nice RGB blue on the left converts to CMYK as 88,77,0,0. A color with 77% magenta is going to print purple; think about the numbers...how can it not? (The swatch on the right is an approximation of that mix as it appears in printed ink.) This is one of the major translation issues...this blue is the one you will get if you choose "blue" from color pickers in Word, for instance, and it's the default blue for hyperlinks. It's also a typical blue from a sunny sky. Beware.

This nice RGB blue on the left converts to CMYK as 88,77,0,0. A color with 77% magenta is going to print purple; think about the numbers...how can it not? (The swatch on the right is an approximation of that mix as it appears in printed ink.) This is one of the major translation issues...this blue is the one you will get if you choose "blue" from color pickers in Word, for instance, and it's the default blue for hyperlinks. It's also a typical blue from a sunny sky. Beware. By Dan Margulis

Published by Peachpit Press, 2006

ISBN 032144017X, 9780321440174

Friday, November 14, 2008

I think I want, you know, like, the shiny paper?

To my understanding "matte" is usually used to describe paper with a dull finish. It is often confused with uncoated paper, but you can actually have a "matte" coating that is still dull in appearance. She then goes for the extra credit points by discussing matte finishes which can be applied after the regular inks go down, but we're limiting our discussion to the paper itself.

The key distinction when describing paper is whether it's coated or uncoated. It's at this point that the term "matte" often jumps in and, as Shelley points out, what people may mean is uncoated as opposed to a coated stock with a matte finish. If you don't know whether the paper you have in mind is coated or uncoated you stand almost no chance of communicating effectively what you are looking for. This is something you REALLY need to know. Here are the details which, for once, are relevant:

The ingredient in the mix which provides the coated aspect is clay (in addition to the routine pulp which all paper contains) providing a much harder, more reflective surface as the mix is rolled out in the paper mill. The coating (or absence of coating) changes radically the amount of light the sheet reflects. Printing inks are transparent...light passes through them and bounces off the paper, and the more light that bounces back the more light energy strikes your eyeball. The more your eyeballs are stimulated by this light the brighter your colors appear. The same ink film printed on coated and uncoated stock will appear as two completely different colors. Beware.

This is relevant in two ways; first because you want to predict what your colors will look like and second because you want to be sure you can describe the paper to be quoted.

Your colors should be previewed by checking them against a Pantone (or similar) printed reference book. (The Pantone.com link is on my main page for reference.) All of these terrific guides come in a coated and uncoated version...if you buy printing regularly, and you don't have them you are an accident waiting for a place to happen. But what if you need a preview of an image where there is no single color applied such as a color photograph or full color graphic?

In such a case, hopefully, your print vendor will supply your color contract proof on an uncoated material; if not you will need some considerable guidance from them about what shifts will transpire when the image is printed. In my experience, printing full color (CMYK) on an uncoated stock will often lead to colors which disappoint the customer, unless a muted effect is desired. It doesn't mean that the paper has to be glossy, but most often a coated stock seems preferable.

Here are your choices, (and we're finally going to get to the "matte" term in it's correct context).

COATED STOCKS: In descending order of "shininess".

Cast Coated text and cover, high mirror gloss, expensive, specialized, easy to confuse with regular gloss which has an extra top coating of gloss laminate, varnish, or UV applied by the printer (not native to the paper itself).

Gloss coated text and cover, nice and shiny, clean color, fast drying, little show through.

Dull coated text and cover, same as above but less shiny, easier to read, non glare surface, can be written on, sometimes needs an extra day dry time.

Matte coated text and cover, least shiny, most texture, quality varies A LOT, drying of ink often unpredictable. We're not crazy about it.

UNCOATED STOCKS

Book paper; Offset and opaque offset, similar to varying grades of paper for your copier or laser printer, inexpensive, low weight (for mailing).

Textured and Textured Cover; Available in a wide range of colors, textures and weights, great tactile properties, sometimes availability problems.

Writing papers; 25% cotton usually with a watermark for use as letterhead, envelopes and matching cards for stationery packages. It isn't cheap but the high level of quality is usually worth it for personalized written communication.

Index, tag, bristol; specialized uses for cards, tags, el cheapo postcards.

So there you have almost the entire universe of printing papers if you can remember eight basic grades. You don't need to know the paper business inside out, but these terms are important. Swatch books are available for typical brands and your vendor can help with the (unbelievably arcane) system of weights which apply. It's much more impressive to say "I want it on gloss text" than to resort to "I think I want, you know, like, the shiny paper?"

I appreciate the responses to last weeks question so much I'm going to use the same approach to gather information for next week. A reader asked about preventing color shifts when going from RGB on her monitor to printed CMYK color. Particularly skin tones which come out looking like the subject has a high fever, and blues which pick up a lot of magenta and say "HELLO, I'M BARNEY THE DINOSAUR"! Any responses will be combined with my own meager knowledge for next weeks post, and one name will be drawn from those who reply for the Atlanta Bread Company goodies. Let's see how much expertise we have out there among you PhotoShop experts.

Until then , see you online!

Hugh Butler

Your friend in the printing business

Friday, November 7, 2008

Gone WRONG, part II

Last week, in honor of Halloween, we suffered through problems with print quality and issues surrounding the printer's proof. This week we continue our bad luck with shortages and delivery. Finally, we'll search for the redemption of understanding in how how to approach these pitfalls, and then be able to move on to more cheerful topics.

Shortage problems: By tradition in the printing business, a delivery of 10% over or under the requested quantity constitutes completion of the order with the invoice pro-rated to reflect the actual amount. (There are actually good reasons why this is so.) By this logic an order for 1000 newsletters is considered complete if the vendor delivers 901 and bills you for that many. For many customers this may be unacceptable, but in the absence of an agreement it's likely what your vendor is thinking. What if your mailing list has 950 names?

Solution: Like so many things we'll discuss, the difference between a deal and a dispute is what you agree to in advance. If the exact quantity is critical specify the order as "1,000 copies, no unders". You will pay slightly more; this is because the vendor will need to purchase some extra stock to guarantee the count even if a small problem is discovered after the presswork is complete. If, however, the count comes up short there will be no dispute about the vendors responsibility to put the job back on the press. The main point is to have a clear understanding with the printer BEFORE the issue comes up.

Hint: Shortage problems often come up when the job is being processed at a mailer. Several possibilities exist; the printer's count may be short, the mailer may have spoiled or misplaced part of the order, or your mailing list may have more names than you anticipated. My first post addressed this last issue (see This will be Win-Win) and if you're joining this blog recently you may want to go back and read it in the archive.

Delivery Problems: Here your job is delivered late, to the wrong destination, or in a manner unsuitable for the destination, (think tractor-trailer showing up at plush office with no loading dock).

Solutions: If any aspect of the delivery is critical that information must be part of the original job specs. If it is then missing from the printers proposal, that fact should be corrected before acceptance, and be stated clearly on any purchase order. It's vital that this kind of information be conveyed (or at least confirmed) in writing and as early as possible in the process.

Hint: There is a WORLD of difference between "I need it next Monday" and "I need it next Monday by 8:30 AM when my boss will present it at a meeting in Tampa". If a delay of one day renders the product unsatisfactory, you need to be clear in advance that's the case and have an agreement about possible contingencies. It is unreasonable to make a claim for delay if information has been withheld and the job is proceeding on a "normal" schedule. Likewise, the vendor must be honest about the progress of your job, and if a delay becomes apparent may need to consider what steps must be taken to avoid a breach of their responsibility.

OK, let's restart the clock and call the vendor to discuss what happened and how to proceed. If the situation is clear cut, hopefully the party involved will own up to their responsibility. If responsibility is not so clear, hopefully the two parties will remember the value of their continued relationship and work to resolve the issue in a way which is mutually satisfactory.

Effective communication before the fact will prevent many..Blah, Blah, Blah, Blah.

You knew I was going to say something like that, and it's true. Just as true, however, is that things go wrong in a fast paced environment like a printshop. Things will also go wrong as long as customers have ten zillion other things to concentrate on besides their printing. When things go wrong after ink is on paper the cost of remedies are substantial, which is why we stress our mutual efforts BEFORE that crucial step has occurred.

Your best idea is to try and understand what's going on in the other person's world, and be aware of how they look at your common goal. If, then, you're clear about YOUR role in the process you can concentrate on doing the best possible job of dotting the "i"s and crossing the "t"s. That way you can open up the box and say "There! Now THAT'S what I expected"!

Here's a question related to next weeks post for your consideration: What does the term "matte" refer to specifically in the printing trade? I'll draw one name at random from any correct (or even close to correct) responses to receive an order of muffin tops from the Atlanta Bread Company, delivered personally by yours truly.

Thanks for stopping by!

Hugh Butler

Your friend in the printing business

Friday, October 31, 2008

Something has gone WRONG!

Here’s the scoop. This week we’ll look averting quality and proof related problems. Next week we'll look at problems with shortages and delivery and try to get a perspective on the issue as a whole.

QUALITY:

Problem: You'll know 'em when you see 'em. Color variation or mis-registration, uneven or incorrect trimming and folding, etc. Pull a few samples from various points in the run and see if the problem is persistent. (Sometimes a few "makeready" or set-up sheets get mixed into the run, and maybe it's not time to push the panic button.)

Solution: Call the vendor and ask for them to come see the samples, and if necessary go through the entire job to sort it out. DO NOT devote your own staff time to this task. DO NOT just suffer the problems in silence. Remedies can range from a sincere apology (minor problem) to a price adjustment (up to about 10%) to an out and out re-run if the product is truly unsatisfactory.

Hint: It's important to be up front about your expectations, and to speak up if you don't like what you receive. Printers work with a wide variety of customers, and some care a lot more about quality than others. You want to be sure they are aware of where you fall within that spectrum, and you will find out rather quickly if that vendor is a good match for your work.

PROOF RELATED PROBLEMS:

The key to understanding proofs is knowing who is supposed to do what:

Vendors are responsible for clarifying the limitations of their proofing system (none are perfect) and explaining what it is the customer is looking at. For instance, if a job prints in spot colors and the proof renders the colors badly, the vendor may need to provide a Pantone ink matching book. Another example is a proof is on white proofing paper, and the customer is unfamiliar with the actual stock...the vendor may need to provide a swatch along with the proof.

Customers are responsible for checking the proof IN DETAIL to be sure nothing goes wrong when the file moves from their system to the vendor's computer. Here are some things to watch out for in particular:

PROBLEMS:

· I can't tell you the number of times people have said to me "you can take this proof back with you right now" after merely glancing through the pages...this is a very dangerous thing to do. Just because nothing has ever gone wrong before doesn't mean this won't be the first time. The consequences of missing something can be dire and your remedies are virtually nil. If you don't understand what you're looking at, don't sign it...it's a contract.

· Beware the option on the proof slip which says "OK with changes" and you decline to see another proof. If there is a subsequent error, even if it's the printer's fault, you have waived your chance to object and the error becomes your responsibility. (Our proof slip doesn't even contain this option because it's so often misunderstood.)

· What about when an error does not show at the proof stage but later shows up in the work? Sometimes a subtle technical graphics problem will arise, and in retrospect the proof has provided only a muted warning. This is a tough one...it's the price we all pay for the convenience and economy of digital proofs. There may be an incompatibility with the vendor's system, or someone may have just screwed up. You may be back to "apologies, price adjustments, re-runs". Its not what the customer or the vendor would like... if you have ANY suspicion that something is wrong make sure you indicate it on the proof and bring it to the vendor's attention.

SOLUTION: Remember the critical importance of proofing because the customer has the ultimate responsibility for this function. If they delegate that role to the vendor they do so at their own risk. Never assume that a problem you see is "just a proofing issue" without the vendor's commitment to verify that's true, and to indicate so on the slip you sign. This will keep you on solid footing if something should go wrong.

HINT: No one knows why an error seems invisible on the proof, but is the first thing you see when you receive the job. A major way to improve your workflow is to stress the importance of your final "in-house" proof among your staff...(maybe even tell them it's the printer's proof to get them to focus). The more correct your file is on the way in, the more you can concentrate on the technical aspects of the printer's proof and not get bogged down on further rounds of editing.

Have a question, comment, or suggestion? Did something happen with a job you don't understand? Amusing (or not so amusing) story to share? Please comment online (can be done anonymously). Almost 100 people read this blog each week so there's a lot of untapped wisdom out there! You can also email me direct, and, as always,

Thanks for stopping by. See you online!

Hugh Butler

Your friend in the printing business

Friday, October 17, 2008

The envelope, please...

Answer: The envelope, definitely.

This is true first because if you design the envelope right away you won't forget it. (You would be AMAZED at the number of holiday cards that show up at our shop with no artwork for the envelope.)

Second, envelopes are only available in certain sizes, and you need to know the size to lay out what's going in it. If you don't you might lay out a card which really has no comfortable fit with envelopes that actually exist. Don't laugh, it happens! If the fit is too tight it's difficult to get the contents in or out, and if the envelope is too big it looks silly.

Here's your link: http://www.belightsoft.com/products/companion/paper/envelopes.php (Thanks to the folks at BeLight Software who publish this wonderful page.) The rule of thumb is that the final size of the contents should be 1/4" smaller in each dimension. For example: An A-7 envelope is 5.25 X 7.25 inches. The folded size of it's card would be 5 X 7. The unfolded size of the card (assuming it's folded and not just a flat card) would be 10 X 7. That's the whole deal.

Third, not every paper in the world is converted into matching envelopes, and even fewer of them are converted and actually stocked by distributors. This means you may fall in love with a paper, and convince your client to love it, only to find either the envelope unavailable, or to be had only in full carton quantities from the mill (1,000 or more). A quick message to your printer can confirm availability before you go ahead.

Most questions arise on the subject of holiday or note cards, so take a look at the link for Announcement or Baronial sizes because these are most commonly used. (One has straight flaps and the other are pointed.) The most popular sizes are A-6, A-8, and A-10 or their baronial counterparts. Square envelopes are also available though not listed in the link...they come in about 1" increments, just remember you will pay extra postage. Again, you can always call or email your printer to check availability.

Advice from 2007: Don't put off layout for your holiday card 'til the third week of December! Be a printing superstar and turn it in about a month in advance... you will stun your colleagues and vendors with your amazing skills. (At our shop you will also get special pricing.)

Keep the size and style link handy, or at least remember it's here. It'll save you revision costs and frustration and, most important, make you look like a hot shot.

Thanks for stopping by!

Hugh

Your friend in the print business

Wednesday, October 8, 2008

How many do you need?

If you need to get a project produced quickly, it's best to know exactly how many to order BEFORE you contact the printer. An order with an indefinite quantity begins life with a loose end, and an opportunity for things to go wrong down the line. Here's the equation:

(Quantity for your current mail list) + (However many over the mailing service will need for set-ups and screw-ups) + (How many copies you want delivered to your office) = GRAND TOTAL

One piece of advice from 2008 so far...DO NOT CUT YOUR QUANTITY TOO LOW. Several projects this year have gone back to press for additional copies when the original quantity was chosen too low, or demand exceeded the customers' bare-bones guess. When you arrive at the Grand Total, ask the printer about rounding up a little and find out if the price increase might be negligible. The price of re-plating the job and going back to press will be many, many times that of adding a comparable quantity to the original order.

The place to plug this step into your time line is when you start the last round of type revisions...that's when you want to get your current list count (which often takes a day or so) and check with the mailer. By the time the artwork is approved, you're ready to go for real!

The bottom line is that an order placed with complete information stands a better chance of proceeding without nasty surprises. It cuts down on the possibility of error, and allows your vendor to get all pertinent information on the work right from the start. They will appreciate it!

There...what do you think? Watch for emails when new posts are published, and if you like it here be sure to tell your friends!

Thanks for stopping by,

Hugh

Your friend in the printing business